Value

The Experts Behind High-Voltage Insulator Casting

With Your Casting Success

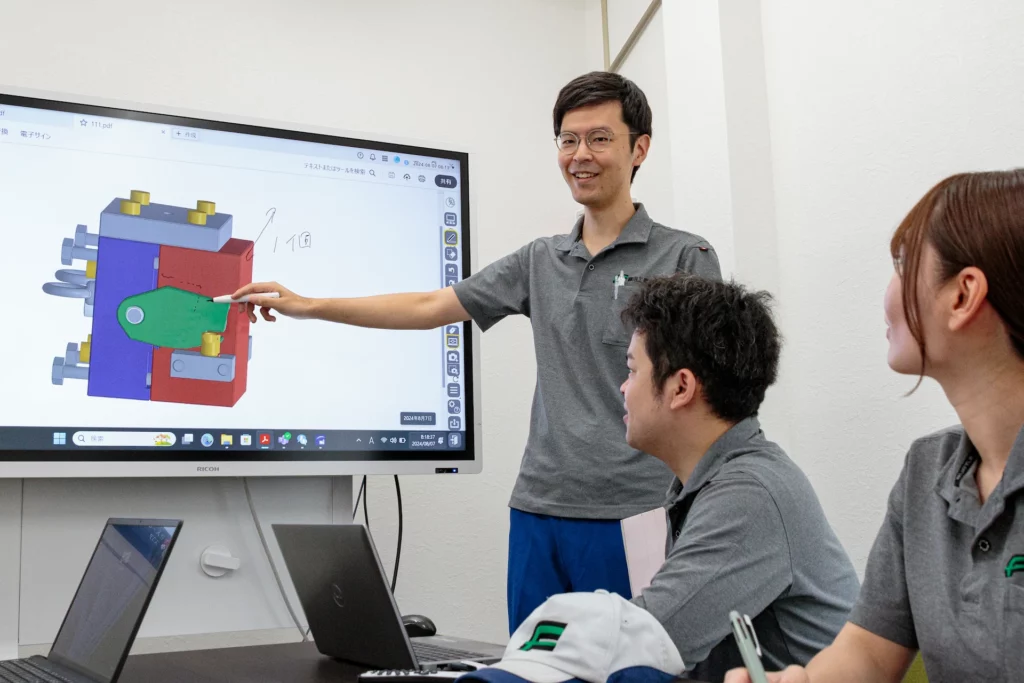

We design precision molds for epoxy and silicone insulator casting, but it is in your shop that our true value exists. By analyzing every step for casting from dosing and vacuuming to curing. We offer you hands-on expertise to increase your productivity and minimize defects. Our continuous support keeps your high-voltage casting line safe, stable, and profitable.

Culture

Your Best Partner in Insulator Casting

― Anywhere in the World

Application-Driven Design

We don’t just ship molds—we map your entire casting workflow, support heat management, vacuum cycles then verify the results onsite. This comprehensive approach enhances the qualities of epoxy and silicone insulators.

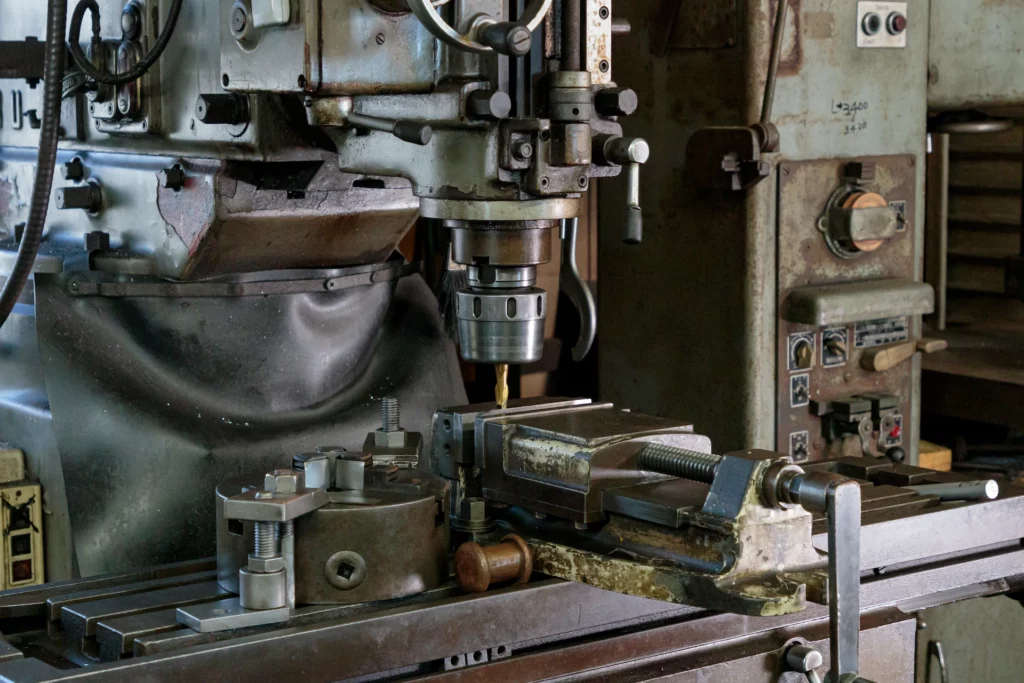

Mold/Tooling

We design APG, vacuum, and compression molds operators love—smooth handling, easy cleaning, and fast changeovers. Precise process and smart design support defect-free epoxy and silicone insulator casting for high-voltage applications worldwide.

Casting Support System

Success requires more than just molds. We supply a range of additional systems to finalize your production from heating circuits to 6-axis deburring robots. Our priority is solving your problems, and we will always support you with our technology.

After-Sales Support ― Worldwide

We provide long-term after-sales support. We always try to solve any issues with your products, even if your equipment is old. Our service team can resolve issues remotely via telephone or video call, or by visiting you on site.